Why a cosmetic packaging mockup is the first step toward the right product

What if the most expensive mistake in your product development occurs before production even begins?

Decisions in cosmetic packaging tend to be made quickly. Shapes are approved, materials are selected and suppliers are aligned. Yet the real turning point often happens earlier, when the packaging mockup takes physical form.

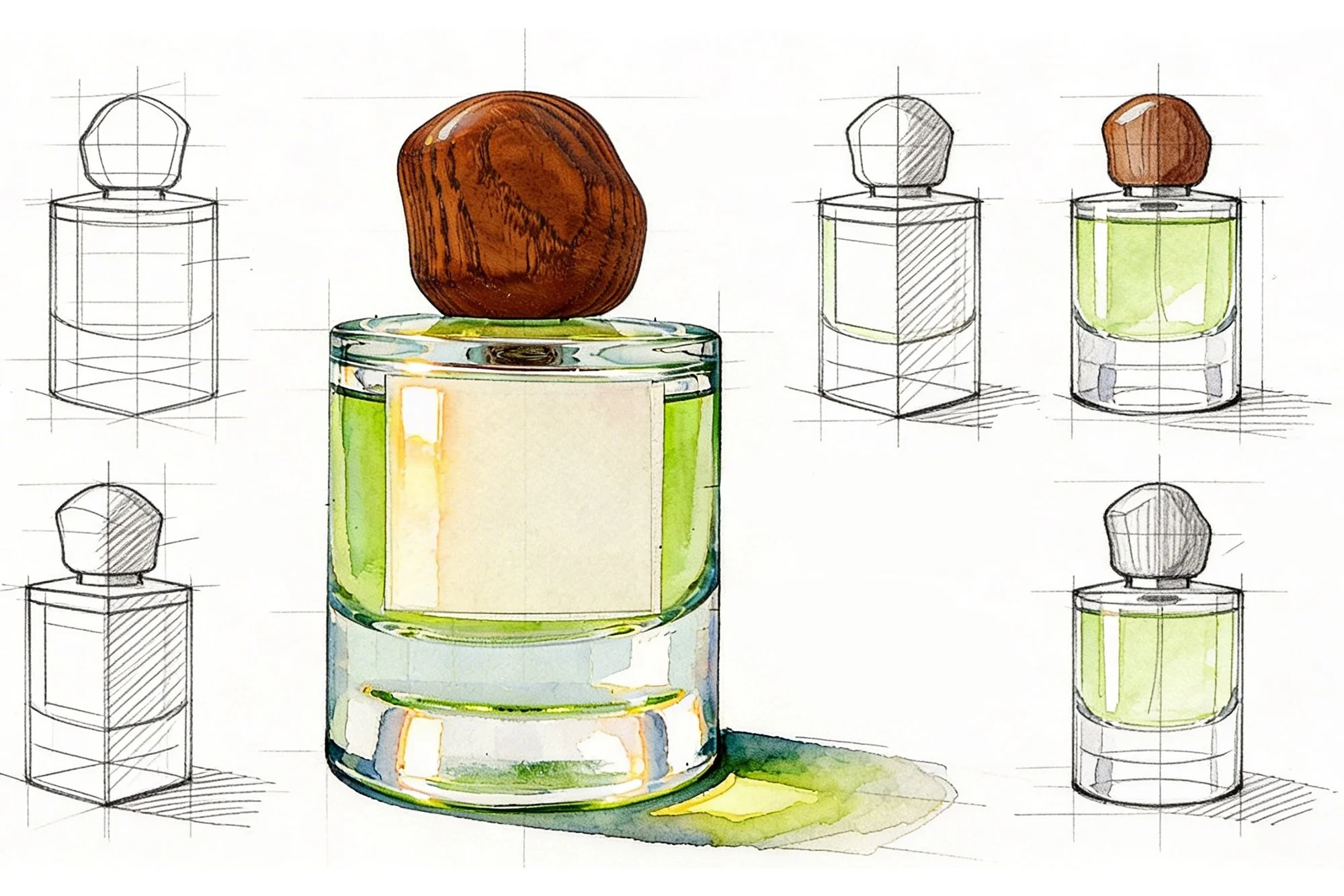

A mockup transforms an idea into something tangible: it enables you to assess proportions, evaluate weight, test closures and observe how materials interact with light, texture and branding. It brings together design, engineering and sustainability, facilitating dialogue between these disciplines long before tooling investments are made.

If you are developing packaging with glass, wood, advanced materials or refill systems, the cosmetic packaging becomes a strategic checkpoint that aligns vision with performance, turning creative direction into a product ready for the market.

What is a cosmetic packaging mockup?

A cosmetic packaging mockup is a full-scale physical model created before industrial production to translate a design concept into something tangible, measurable and discussable. This is the stage at which a packaging idea stops being a visual proposal and starts to behave like a real object with weight, balance, proportions and material presence.

A mockup should not be confused with a prototype or pre-production sample. A mockup is primarily a design validation tool, allowing teams to assess aesthetics, volumes, finishes and material combinations at actual size. A prototype goes further, integrating functional systems such as closure mechanisms or engineered inserts to test performance and compatibility. A pre-series represents industrial validation and is produced using final processes and materials to confirm manufacturing consistency before full production.

In the development of complete cosmetic packaging solutions, mock-ups play a strategic role. It enables brands and technical teams to evaluate:

the relationship between materials, such as glass and FSC®-certified wood;

the balance and ergonomics of the object in hand;

the coherence between design intent and structural feasibility;

the visual impact of finishes, textures and proportions.

Introducing a physical checkpoint early in the process reduces uncertainty and aligns creative, technical and industrial decisions. For companies working on integrated packaging systems, including caps, engineered closures and coordinated glass formats, the mockup is the first concrete expression of the finished product.

READ ALSO:

What is the most sustainable skincare packaging

What are the three C’s of packaging?

Why brands should never skip the mockup phase?

Design validation

The mockup phase is where strategic clarity takes shape. Before investing in tooling or industrialisation, you can see how volumes, proportions and materials interact at actual size. A mockup of cosmetic packaging enables design teams to evaluate balance, shelf impact and consistency across a product line.

At this stage, the worlds of cosmetic packaging engineering and creative direction converge. Decisions regarding glass thickness, wood geometry, closure dimensions and overall ergonomics can be finalised early on, ensuring that the final product reflects both aesthetic intent and structural logic.

Functional testing

Beyond appearance, packaging must perform well. A mockup enables the initial verification of closure alignment, fit accuracy and user interaction. Even before full prototyping, it provides insight into how the packaging will feel and function.

Early validation supports overall packaging performance and helps anticipate adjustments before moving into more complex and costly technical development.

Material evaluation

Material selection defines perception, durability and sustainability impact. During the mock-up phase, you can evaluate the tactility and compatibility of finishes and elements such as wood, glass and advanced bio-based materials.

Sustainable material validation also begins at this stage. Assessing factors such as weight, density, surface treatment and visual consistency ensures that material choices align with brand positioning and regulatory expectations before scaling up production.

From mockup to finished packaging: our approach

A cosmetic packaging mock-up only becomes valuable when it leads to something concrete. Our goal is not to validate a shape in isolation, but to develop a comprehensive packaging system that is technically, visually and industrially sound.

At mPackting, every custom cosmetic packaging mockup is developed as the basis for a finished product. From the outset, we study wood, glass and pump systems together. Proportions, tolerances and mechanical interfaces are aligned from the outset, ensuring that design intent and engineering logic evolve in tandem.

The process moves through clear stages.

First, the packaging architecture is defined as a whole, including the cap, internal mechanism, glass bottle or jar and, where required, the refill structure. Each element is evaluated in relation to the others, rather than in isolation.

Then materials are integrated with precision. FSC®-certified wood, traceable biopolymers and bio-based systems are combined with selected glass formats and compatible pump technologies. Thanks to our trusted industrial partners, we are able to offer a comprehensive cosmetic packaging development service, providing a coherent technical direction even when multiple materials and suppliers are involved.

Cap geometries, finishes, textures, engraving, proportions and visual balance are all refined to ensure that the final product has a clear identity and can be manufactured on a large scale.

The sustainability of the product is assessed in practical terms, considering material traceability, responsible sourcing, controlled material use and end-of-life considerations that are aligned with current regulations.

Are you developing your next product and looking to progress from concept to a fully engineered, production-ready packaging system? If so, let's start the conversation.

Share your idea, your constraints and your material ambitions. We’ll help you turn them into a validated mock-up and guide the development towards a complete solution that is technically sound and sustainably designed.

Find out more at mpackting.com, or contact us to co-develop your next packaging project.